Ohio State University researchers have created the first wearable sensor designed to detect and monitor muscle atrophy.

A condition involving the loss of skeletal muscle mass and strength, muscle atrophy can happen for a variety of reasons, but is typically a side effect of degenerative disease, aging, or muscle disuse. And frequent testing to monitor muscle atrophy with MRI, the current standard, can be time-consuming and costly.

However, this new study published in the journal IEEE Transactions on Biomedical Engineering suggests that an electromagnetic sensor made out of conductive “e-threads’” could be used as an alternative to frequent monitoring using MRI.

To validate their work, researchers fabricated 3D-printed limb molds and filled them with ground beef to simulate the calf tissue of an average-sized human subject. Their findings showed that they were able to demonstrate the sensor could measure small-scale volume changes in overall limb size, and monitor muscle loss of up to 51%.

“Ideally, our proposed sensor could be used by healthcare providers to more personally implement treatment plans for patients and to create less of a burden on the patient themselves,” says Allyanna Rice, lead author of the study and a graduate fellow in electrical and computer engineering at The Ohio State University.

The first known approach to how to monitor muscle atrophy using a wearable device, the study builds on Rice’s previous work in creating health sensors for NASA. The space agency is interested in monitoring the health of astronauts in a variety of ways, as spending large amounts of time in space can often have detrimental effects on the human body.

Researchers have spent decades trying to understand and combat these effects, and this study was inspired by the goal of finding solutions to health issues facing astronauts.

For instance, while scientists know that even crew members on short spaceflights can experience up to a 20% loss in muscle mass and bone density, there isn’t much data on what effect living in space for much longer missions could have on their bodies, Rice says.

“Our sensor is something that an astronaut on a long mission or a patient at home could use to keep track of their health without the help of a medical professional,” she says.

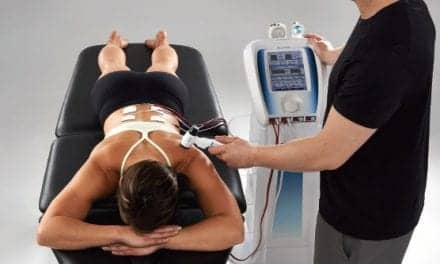

But creating a wearable device capable of accurately measuring minute muscle changes in the human body is easier said than done. Rice and her co-author Asiminia Kiourti, a professor in electrical and computer engineering at Ohio State, designed the device to work by employing two coils, one that transmits and one that receives, as well as a conductor made out of e-threads that run along the fabric in a distinct zig-zag pattern.

Though the final product resembles a blood pressure cuff, Rice said it was originally a challenge to find a pattern that would allow for a wide range of changes to the size of the sensor’s loop so it would be able to fit a large portion of the population.

“When we first proposed the sensor, we didn’t realize that we would need a stretchable material until we realized that the person’s limbs were going to be changing,” she says. “We need a sensor that can change and flex, but it also needs to be conformal.”

After some trial and error, they found that while sewing in a straight line would limit the sleeve’s elasticity, a zig-zag pattern was ideal for amplifying it. This same novel pattern is the reason the sensor may be scalable across multiple different body parts or even several locations on the same limb.

Though the wearable is still years away from implementation, the study notes that the next major leap would most likely be to connect the device to a mobile app, one that could be used to record and deliver health information directly to healthcare providers.

And to improve life for future patients both on Earth and in space, Rice is looking forward to combining the sensor with other kinds of devices for detecting and monitoring health issues, such as a tool for detecting bone loss.

“In the future, we would like to integrate more sensors and even more capabilities with our wearable,” Rice says.

This work was supported by NASA.